JETSCI KolorSmart+

Redefining Efficiency, Quality, and Versatility

The JETSCI KolorSmart+ Digital Label Press has comprehensive features to meet the diverse needs of various industries. Combining speed, precision, versatility, and customization, this press has gained recognition for its ability to deliver high-quality labels efficiently.

Higher Flexibility

High Quality

Great Value Addition

Profitability

Fast Turnaround Time

Increased Productivity

The technology

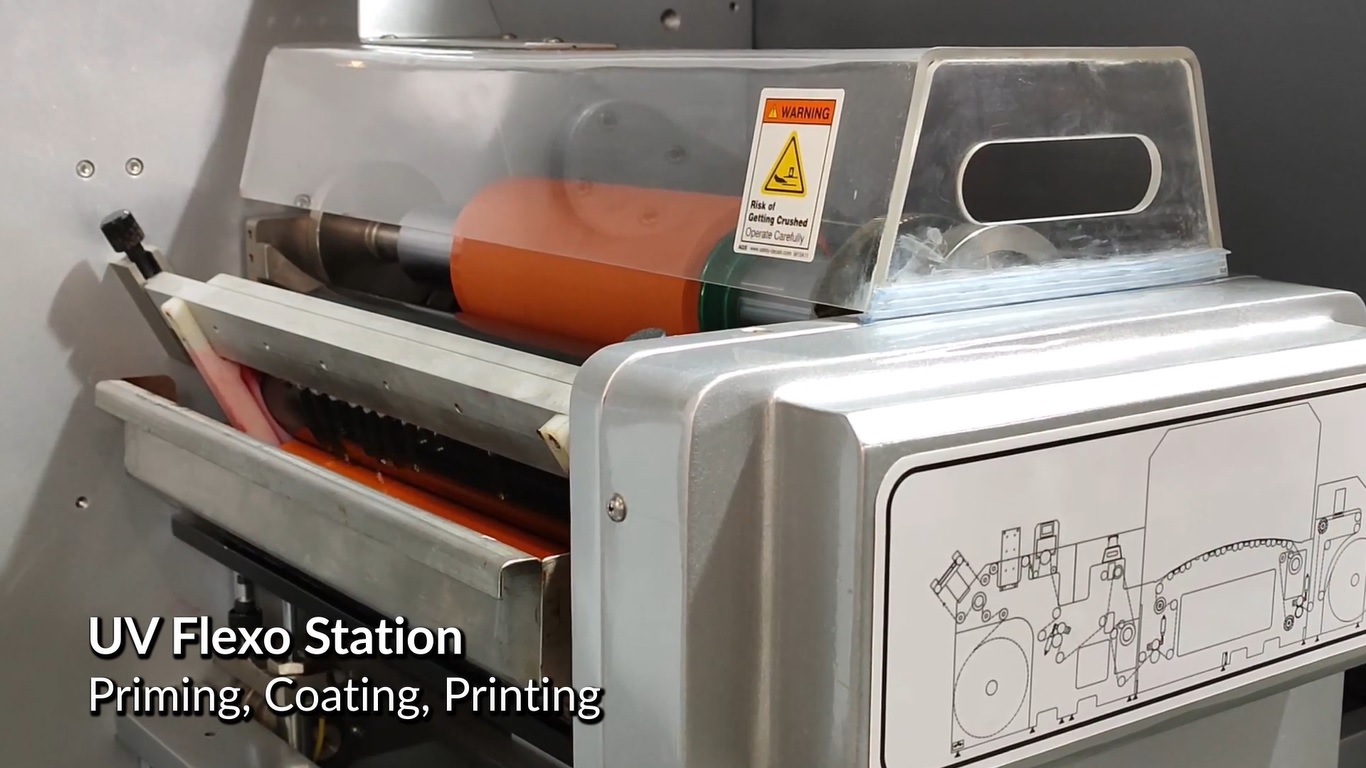

The press is having an additional pre-inkjet flexo station with standard UV curing to apply primers, under white or spot colours.

Pre-Inkjet flexo station can be used for priming, coating, or single-color printing along with up to 6-colors (W+CMYK+ Special color).

UV Inkjet unit 4-step gray droplet size printheads level printing with specially formulated ink gives excellent image quality and sharp text with fine details. The press utilises inkjet print head technology from Kyocera providing uncompromised quality.

At the core of the KolorSmart+ lies advanced printing technology that sets it apart in the market. Equipped with high-resolution printheads with gray scale and a sophisticated color management system, it promises exceptional print quality.

One of the standout features of the KolorSmart+ is its consistent printing speed. Capable of handling high volumes of label production at a rapid pace, this press caters to businesses requiring efficiency without compromising quality.

Its user-friendly interface simplifies the printing process, reducing the learning curve for operators. Moreover, its automation capabilities streamline operations, minimizing manual intervention and potential errors, thereby enhancing overall efficiency.

In a market where personalization and customization are increasingly valued, the press with its digital nature allows for easy customization and tailoring of labels to specific requirements. This feature proves invaluable for businesses aiming to create unique and personalized labels for their products, thereby enhancing brand identity and customer engagement.

Applications Across Industries

Food and Beverage

In the food and beverage industry, the KolorSmart+ finds extensive application in labeling products with intricate designs, nutritional information, and branding elements while maintaining visual appeal.

Pharmaceuticals and Healthcare:

Precision and accuracy are crucial in pharmaceutical labeling. The KolorSmart+ excels here, producing high-quality labels with clear dosage instructions, barcodes, and other vital information, ensuring compliance and safety for consumers.

Cosmetics and Personal Care

With the demand for aesthetically pleasing packaging in cosmetics, the KolorSmart+ fulfills the need for vibrant, detailed labels that enhance product presentation. Customization options cater to different sizes and shapes of containers, amplifying brand recognition.

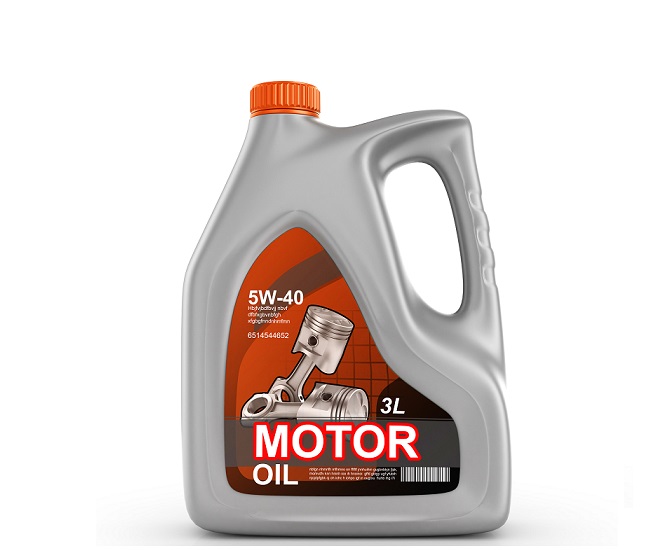

Industrial and Chemical Labels

Labels in these sectors often require durability and resistance to harsh environments. The KolorSmart+ offers solutions for robust and resistant labeling, incorporating safety information, handling instructions, and compliance details.

Businesses often require printing on various substrates, and the JETSCI KolorSmart+ excels in this aspect. It supports a wide range of label materials, enabling printing on diverse surfaces without compromising on the quality of the output. No matter what your printing requirement, KolorSmart+ is versatile to print labels across diverse industries.

Ease of Use

Its user-friendly interface simplifies the printing process, reducing the learning curve for operators. Moreover, its automation capabilities streamline operations, minimizing manual intervention and potential errors, thereby enhancing overall efficiency.

Versatility

The press is having an additional pre-inkjet flexo station with standard UV curing to apply primers, under white or spot colours.

Pre-Inkjet flexo station can be used for priming, coating, or single-color printing along with up to 6-colors (W+CMYK+ Special color).

Excellent Quality

UV Inkjet unit 4-step gray droplet size printheads level printing with specially formulated ink gives excellent image quality and sharp text with fine details. The press utilises inkjet print head technology from Kyocera providing uncompromised quality.

At the core of the KolorSmart+ lies advanced printing technology that sets it apart in the market. Equipped with high-resolution printheads with gray scale and a sophisticated color management system, it promises exceptional print quality.

Robust and Productive

One of the standout features of the KolorSmart+ is its consistent printing speed. Capable of handling high volumes of label production at a rapid pace, this press caters to businesses requiring efficiency without compromising quality.

Specifications

|

TECHNICAL SPECIFICATION |

|

| Print head | Piezo DoD, Gray Scale |

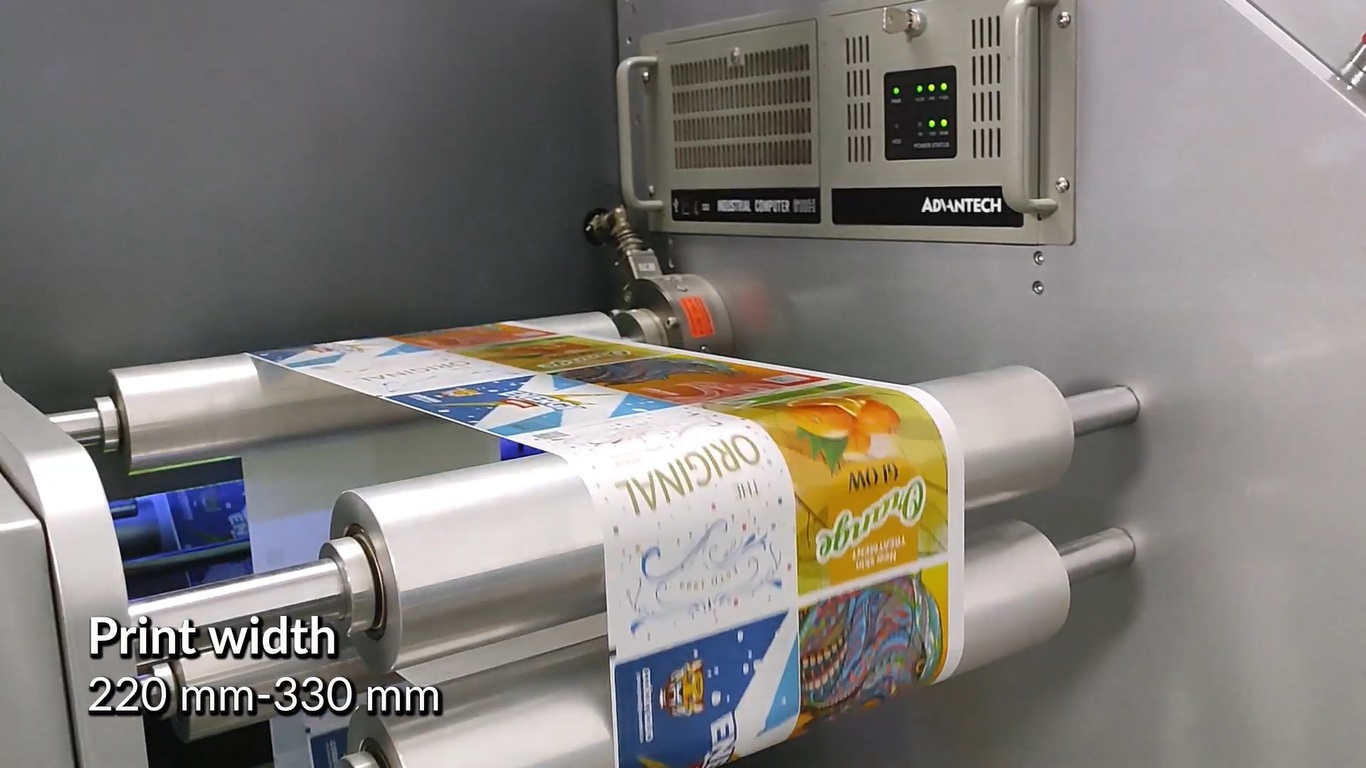

| Web Width | Up to 350 mm |

| Speed | Up to 50 m/min |

| Drop Volume | 3-14 pL (4 Gray level) |

| Substrate | 40-200 um (label paper supported, other materials – perform test) |

| Air Supply Requirement | Compressed Air, 6-8 Bar, Moisture & Oil Free |

| Ink Systems | Closed Loop with Degas |

| Ink Tanks | 5 Litres(To be Specified) |

| Color | CMYK + White + Special Color |

| Electrical Requirements | 3 phase 410-440 V, 50-60 Hz, 32 A |

| Ink type | UV LED Curable, Hi-opacity White |

| Dimension | 4550 x 2175 x 2050 mm & Weight – 1800 Kg |

| DIGITAL PRINT ENGINE | |

| Print Width | Up to 324 mm |

| Resolution | 600 x 600 dpi native, @ 4 level Gray scale, 600×1200 dpi Configurable |

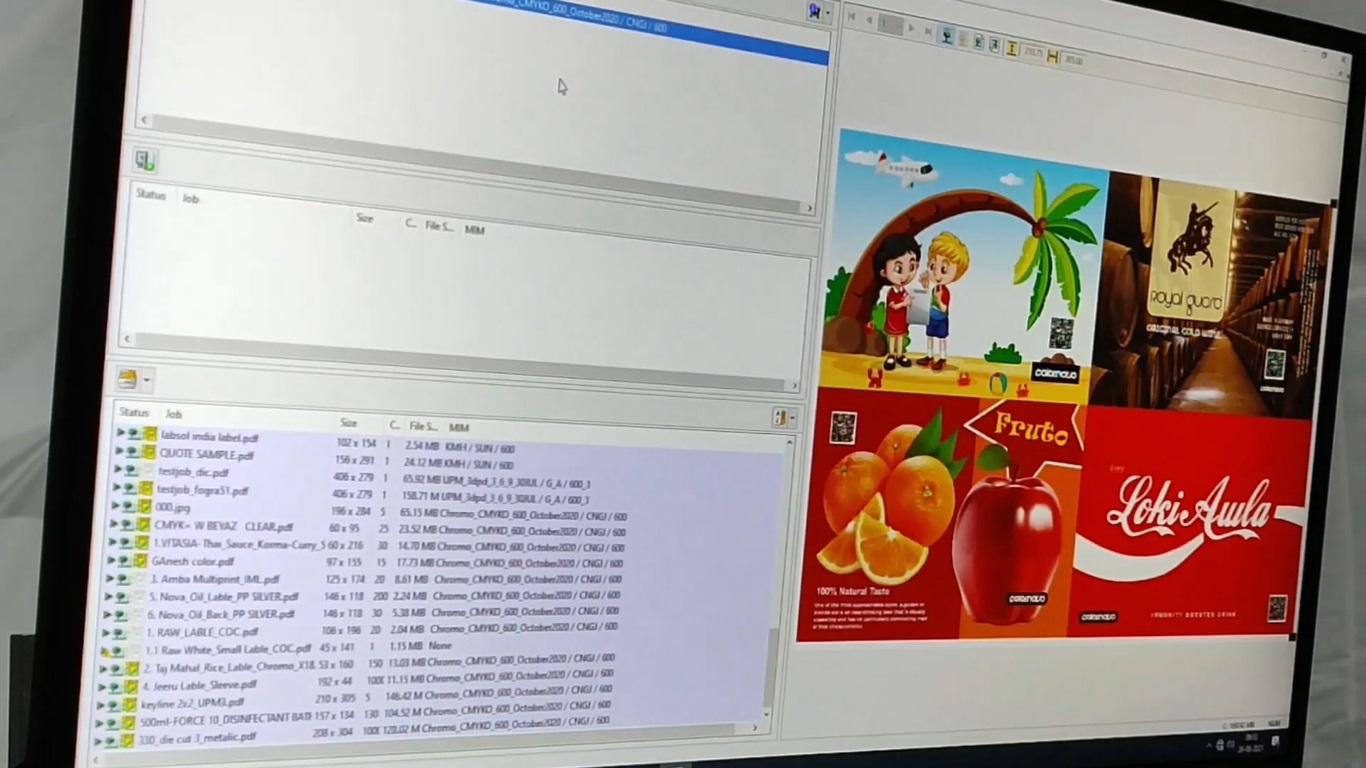

| File Format | PDF, PDF/VT, TIFF, JPEG, BMP & other database files |

| Workflow | Advanced Color, Management and Solution |

| Ink Curing | Inter Colour UV LED Pinning, Full Curing by UV LED / Arc Lamp, Chilled Drum Rollers |

| WEB CONTROL SYSTEM (Fully Servo Driven) | |

| Unwinder Diameter: | 700 mm, core 76 mm |

| Rewinder Diameter: | 700 mm, core 76 mm |

| Other Accessories: | Pre-Inkjet Flexo Station, Web Cleaner with Antistatic Bar, Corona Treater |

| Flexo unit | Coating, Printing, Primer with UV Curing |

| ENVIRONMENTAL DATA | |

| Optimal Temperature Range: | 20-24°C (68-72-degree F) |

| Ink Storage | 18-22°C (68-77-degree F) |

| Optimum Humidity Range | Humidity 40-60%, Non Condensing |